Explore the Advantages of Fanless Industrial PCs Today

Understanding Fanless Industrial PCs: Features, Advantages, and Applications

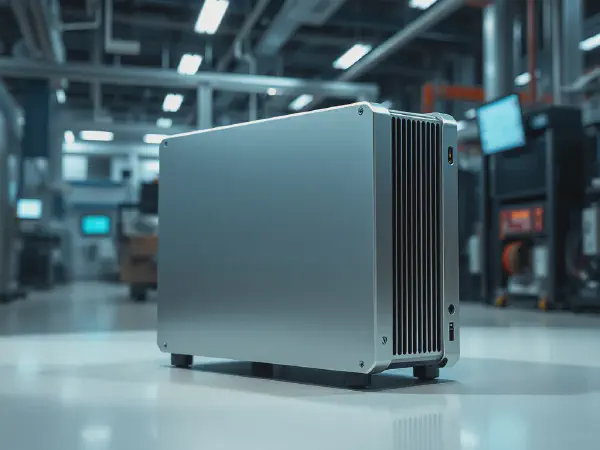

Fanless Industrial PCs are specialized computing devices designed to operate without cooling fans. These systems rely on passive cooling techniques, making them ideal for environments where dust, moisture, and temperature variations can compromise performance. With no moving parts, Fanless Industrial PCs offer durability and reliability for demanding industrial applications.

For a seamless typing experience in any environment, consider investing in a reliable water proof keyboard that withstands spills.

The design of Fanless Industrial PCs is a key factor in their performance. These devices often feature a compact form factor with a minimalist aesthetic, suitable for integration into various industrial settings. Additionally, they utilize advanced heat dissipation methods, such as heat sinks and thermal conduction, to manage internal temperatures efficiently without the use of fans.

One of the significant advantages of Fanless Industrial PCs is their silent operation. Without the noise generated by fans, these PCs can be deployed in quiet environments, such as medical facilities and research labs, where low acoustic levels are crucial. Moreover, their energy-efficient designs reduce electricity consumption, leading to lower operational costs over time, essential for organizations looking to optimize budgets.

Fanless Industrial PCs are built to last. The lack of mechanical components like fans minimizes wear and tear, extending the lifespan of the devices. They are also resistant to particulates and liquids, making them highly reliable in harsh industrial conditions. As a result, many manufacturers are turning to fanless solutions to ensure their technologies can withstand rigorous operational demands.

In recent years, Fanless Industrial PCs have found their place across various applications. They are commonly used in industrial automation and control systems, where robust performance is essential. Their reliability and compact size also make them suitable for transportation and logistics management. Furthermore, Fanless Industrial PCs play a critical role in medical devices and healthcare technologies, contributing to safer and more efficient patient care.

Design and Architecture of Fanless Industrial PCs

Fanless Industrial PCs are characterized by their minimalist design elements, prioritizing functionality and efficiency. These systems often have streamlined chassis that not only enhance aesthetics but also facilitate heat dissipation. The absence of fans allows for a sealed design, minimizing dust accumulation and improving reliability in challenging environments.

To manage heat, Fanless Industrial PCs employ several innovative methods. Most use large aluminum heat sinks that dissipate heat away from critical components. Additionally, thermal conduction through the chassis allows heat to be transferred to the outer casing, keeping internal temperatures within safe operating limits. This design philosophy ensures that the systems can maintain peak performance without relying on airflow.

The detailed rk200-03 pyranometer manual provides essential guidelines for accurate solar radiation measurements essential for research.

The materials used in constructing Fanless Industrial PCs are selected for their thermal properties and durability. Aluminum is a common choice due to its lightweight and excellent thermal conductivity. Some systems even use rugged enclosures made of stainless steel to resist corrosion and withstand harsh conditions, ensuring longevity and performance even in extreme environments.

In a world driven by connectivity, the efficiency of a 4g sms modem ensures your messages are transmitted without delay.

Advantages of Fanless Industrial PCs

One of the most significant benefits of Fanless Industrial PCs is their noise reduction capabilities. The silent operation of these devices eliminates the disruptive sounds typically generated by spinning fans, making them ideal for sensitive environments such as offices, hospitals, and labs. This feature not only enhances user experience but also contributes to a more comfortable and productive work atmosphere.

Fanless systems also excel in energy efficiency, often consuming less power compared to their traditional counterparts. This lower energy requirement results in reduced electricity bills, making fanless PCs an economical choice for organizations aiming to reduce overhead costs. Over time, this cost-effectiveness can lead to substantial savings, impacting the overall financial health of a business.

The longevity and reliability of Fanless Industrial PCs are further nail it in high-demand applications. With fewer moving parts, these systems experience less wear and tear, translating to a longer operational life. This increased reliability is crucial for mission-critical applications, where downtime can result in significant operational losses.

Applications of Fanless Industrial PCs

Fanless Industrial PCs are revolutionizing industrial automation and control systems by providing reliable computing solutions in challenging environments. These systems can integrate with various sensors and machinery, streamlining processes and improving operational efficiency. Their robustness ensures they perform well even under heavy workloads, a requirement in modern manufacturing and automation.

In transportation and logistics, Fanless Industrial PCs play an essential role in managing real-time data and monitoring systems. They can withstand vibrations and temperature fluctuations commonly encountered in vehicles and machinery, making them reliable components in transport management systems and cargo tracking solutions.

The healthcare sector also benefits from Fanless Industrial PCs, which power medical devices and systems that require stringent operational standards. Their silent operation is indispensable in hospitals and clinics, where noise can interfere with patient care. Additionally, the robust design ensures that these PCs can withstand disinfection processes and provide long-term reliability for critical healthcare applications.

Comparative Analysis: Fanless vs. Traditional PCs

When comparing performance metrics, Fanless Industrial PCs can match or exceed those of traditional PCs in many aspects. While traditional systems may have higher processing power due to their cooling mechanisms, Fanless PCs utilize efficient designs that maximize performance while maintaining lower power consumption. This balance allows them to perform effectively in many similar applications without overheating.

Maintenance is another crucial aspect where Fanless Industrial PCs outperform conventional units. The absence of fans significantly reduces the need for regular maintenance, such as cleaning dust from cooling systems. This advantage is particularly important in industries where uptime is crucial, allowing businesses to allocate resources to other essential tasks while ensuring reliability.

Cost analysis reveals that although Fanless Industrial PCs may have a higher initial investment, their long-term benefits often outweigh the costs. Reduced energy consumption, less frequent maintenance, and extended equipment lifespans contribute to a better return on investment over time, making them appealing for companies looking at sustainable technology solutions.

Future Trends in Fanless Industrial PC Technology

Emerging technologies are continually shaping the landscape of Fanless Industrial PCs. Innovations in semiconductor materials and cooling techniques are paving the way for more powerful and compact designs. As manufacturers work towards enhancing performance while maintaining fanless operations, we can expect to see exciting advancements in processing capabilities and energy-efficient solutions.

Predicted market trends indicate a growing demand for Fanless Industrial PCs. With industries increasingly prioritizing sustainability and energy efficiency, the shift towards fanless designs is likely to accelerate. As more industries adopt automation and IoT technologies, the need for reliable, noise-free computing will further drive innovation in Fanless Industrial PCs.

The rise of the Internet of Things (IoT) is significantly influencing the development of Fanless Industrial PCs. As connectivity and smart technologies become more ubiquitous, fanless systems will evolve to support the vast amounts of data produced by IoT devices. This shift will require them to integrate seamlessly into smart ecosystems, providing the necessary computing power in compact form factors.